Introduction

The PPR brass male socket is a key component in industrial piping systems. It combines polypropylene random copolymer (PPR) with brass to offer a robust connection solution. This fitting is designed to connect PPR pipes to brass components, making it suitable for various industrial applications. This article explores the industrial uses of the PPR brass male socket, highlighting its benefits and providing specific examples.

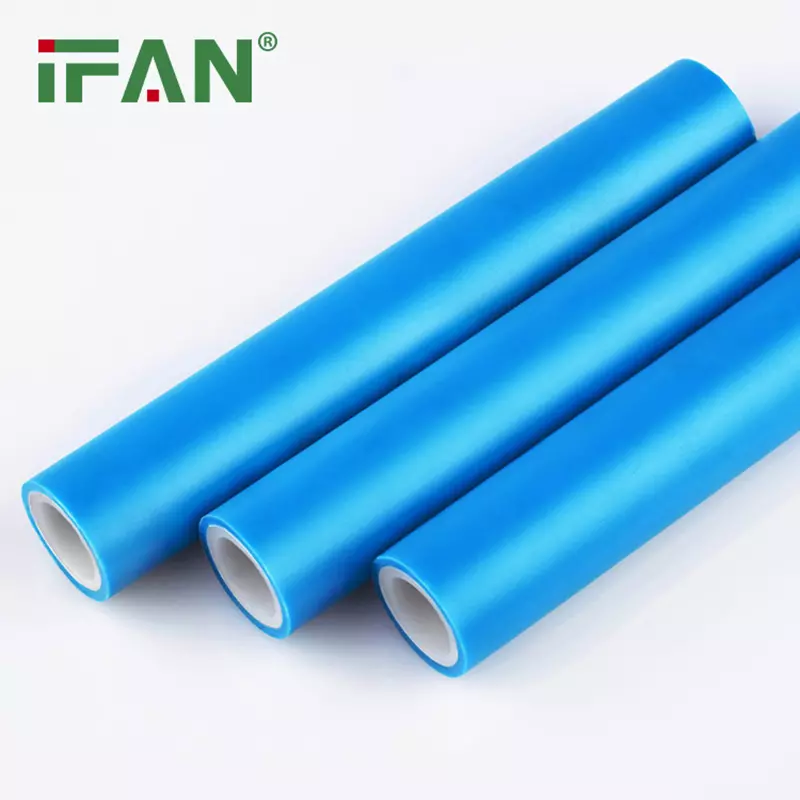

Product Information

| Product Name |

IFAN Polypropylene Green PPR brass male socket |

| Color |

Green,White,Grey,Yellow,Blue,Coffee Color Or Customized |

| Size |

20-125mm Or Customized |

| Material |

PPR |

| Package |

Opp Bag+Cartoon |

| Standard |

ISO 15874,EN 15874,ASTM F2389,DIN 8077/8078,GB/T 18742,NBR 15884 |

| OEM |

Aviable |

| Sample |

Free Provide |

| Contact US |

Whatsapp:+8613373827623 E-mail:[email protected] |

We have 30+ years of plumbing experience, a wide range of products, support customization and free samples. This IFAN Facebook:https://www.facebook.com/IFANPiping, welcome to contact us. If you are interested in IFAN’s PPR Pipe Fittings, please feel free to send us a message; we will send you the price list and product catalogue in time.

Material Strength and Durability

In industrial settings, the strength and durability of materials are crucial. PPR brass male sockets excel in these aspects due to their composition. The PPR part offers resistance to chemical corrosion and high temperatures, while the brass insert provides additional mechanical strength. For instance, in a chemical processing plant, where pipes handle aggressive chemicals, the PPR brass male socket can withstand both the corrosive effects of chemicals and the mechanical stresses of high-pressure systems.

Connecting PPR Pipes with Metal Components

One of the primary industrial applications of the PPR brass male socket is connecting PPR pipes to metal components. In many industrial systems, PPR pipes are used due to their flexibility and cost-effectiveness. However, metal components are often necessary for certain connections. The PPR brass male socket serves as a transition fitting, bridging the gap between PPR pipes and metal parts. For example, in a water treatment facility, PPR pipes carrying treated water can be connected to brass valves or gauges using PPR brass male sockets.

High-Pressure Systems

Industrial systems frequently operate under high pressure, making the choice of fittings critical. PPR brass male sockets are designed to handle high-pressure conditions. The brass insert ensures that the fitting can withstand the pressure without deforming or leaking. In an oil and gas refinery, where pipelines carry pressurized fluids, PPR brass male sockets are used to connect PPR pipes to metal fittings, ensuring a secure and leak-proof connection that can handle the operational pressures.

Chemical Resistance

In industrial applications involving chemicals, resistance to chemical corrosion is essential. PPR brass male sockets provide this resistance due to the properties of PPR and brass. The PPR material resists a wide range of chemicals, while the brass insert provides additional protection. For example, in a chemical manufacturing plant, where pipes transport various corrosive substances, PPR brass male sockets are used to connect pipes to fittings and valves, ensuring the system remains intact and functional.

Temperature Variability

Industrial environments often experience wide temperature fluctuations. PPR brass male sockets are designed to perform well under varying temperatures. The PPR material can withstand temperatures up to 95°C (203°F), while brass maintains its strength across a broad temperature range. In a power plant, where pipes may carry hot steam or cold water, PPR brass male sockets provide a reliable connection that remains stable despite temperature changes.

Ease of Installation and Maintenance

Ease of installation and maintenance are significant advantages of using PPR brass male sockets in industrial applications. The fusion process for connecting PPR pipes to the socket is straightforward and quick. The threaded brass end simplifies the connection to other metal fittings. For example, in an industrial HVAC system, PPR pipes can be easily connected to brass components using PPR brass male sockets, reducing installation time and facilitating easier maintenance.

Cost-Effectiveness

Cost-effectiveness is a key consideration in industrial projects. PPR brass male sockets offer a balance of affordability and performance. The use of PPR reduces material costs compared to all-metal fittings, while the brass insert provides the necessary strength and durability. In large-scale industrial installations, such as in manufacturing plants, the cost savings from using PPR brass male sockets can be substantial while still ensuring a reliable and durable connection.

Integration with Automation Systems

In modern industrial systems, automation plays a crucial role. PPR brass male sockets are often used to integrate PPR piping systems with automated control systems. The ability to connect PPR pipes to brass sensors, actuators, and control valves is essential for efficient automation. For instance, in an automated water distribution system, PPR brass male sockets connect PPR pipes to brass sensors and valves, allowing precise control and monitoring of water flow.

Compliance with Standards

Industrial applications require compliance with various standards and regulations. PPR brass male sockets are designed to meet industry standards for safety, performance, and reliability. They are manufactured to ensure they can withstand the rigors of industrial environments while maintaining compliance with relevant codes. For example, in a food processing facility, PPR brass male sockets are used to connect pipes in compliance with sanitary standards, ensuring that the system remains hygienic and safe.

Environmental Impact

In industrial applications, the environmental impact of materials is increasingly important. PPR brass male sockets contribute to environmental sustainability due to their long lifespan and recyclability. The PPR material is recyclable, and brass can be recycled as well. By reducing the need for frequent replacements and supporting recycling, PPR brass male sockets help minimize waste and promote environmental responsibility. In an industrial setting, this contributes to the overall sustainability of the operation.

IFAN International Standard for PPR Tubing

IFAN recognizes several important standards for PPR (polypropylene random copolymer) piping systems to ensure their quality and performance. These include ISO 15874 and EN 15874, which set international standards for PPR pipes and fittings; ASTM F2389, which specifies requirements for PPR pipes used in pressure applications; DIN 8077/8078, which provides specifications for PPR pipes and fittings in Germany; GB/T 18742, which covers PPR pipes in China; and NBR 15884, which outlines standards for PPR pipes and fittings in Brazil. These standards collectively ensure that PPR products meet rigorous global quality and performance criteria.

Conclusion

PPR brass male sockets are essential components in industrial piping systems, offering strength, durability, and versatility. Their ability to connect PPR pipes to metal components, withstand high pressures, resist chemicals, and perform under varying temperatures makes them suitable for a wide range of industrial applications. From chemical processing plants and oil refineries to power plants and automated systems, PPR brass male sockets provide reliable and cost-effective solutions. Their ease of installation, compliance with standards, and environmental benefits further enhance their value in industrial settings. Understanding these applications helps in selecting the right fitting for various industrial needs, ensuring efficient and sustainable operations.

FAQ

1.What products does IFAN produce?

IFAN integrates R&D, production, sales and service, and provides comprehensive plumbing system solutions. The company’s main product lines cover construction engineering, municipal pipelines, agricultural irrigation, home improvement, fire protection, industrial pipelines, gas pipelines, bathrooms and other systems, providing water supply, drainage, waterproofing, floor heating, bathing, hardware plumbing and other modules. The company provides a variety of products such as pipes, pipe fittings, valves, etc., covering PP-R, PVC-U, Ball Valve, Water Tap, PEX, CPVC, PP and other series.

2.Where is IFAN export factory located in?

No. 3, Central Road, Diankou Town, Zhuji City, Shaoxing City, Zhejiang Province

3.How is the package?

1. Our outer boxes are generally in the format of IFAN unified boxes, and OPP bags and cartons are uniformly packaged. 2. Our products usually use different packaging according to different product types. 3. In addition, we can also customize packaging according to different needs. Adopt customer opinions on product packaging, design packaging and customize Logo.

4.Why should I choose you among so many factories?

1. IFAN products have deeply covered many countries around the world, with rich product varieties, complete qualifications, and strong brand influence, helping you to expand the market faster. 2. We have a stable sales team and long-term experience, and can grasp customer needs in time. 3. Mutual benefit and win-win can lead to sustainable development. 4. Provide customers with perfect after-sales service

5. What is your product advantage?

1. From production to shipment, we have advanced production machines and a very strict management system. 2. Our products are designed, molded, and produced in accordance with international standards. Quality control mainly includes the inspection of the first piece, process, packaging, and finished products. Only qualified products are packaged. 3. We not only have our own laboratory for testing, but also send samples to authoritative certification agencies every year to ensure the long-term quality of products. 4. Our products have different connection methods, including glue, hot melt, electric fusion, thread, etc., which can meet different needs. 5. Our product prices are very competitive, and the company provides free samples to let customers see the quality of the products.

评价

目前还没有评价