Introduction

PPR sockets are essential components in industrial piping systems. Their properties make them ideal for various applications, including water supply, chemical transport, and air conditioning. Understanding their role in these systems can help industries optimize performance.

Product Information

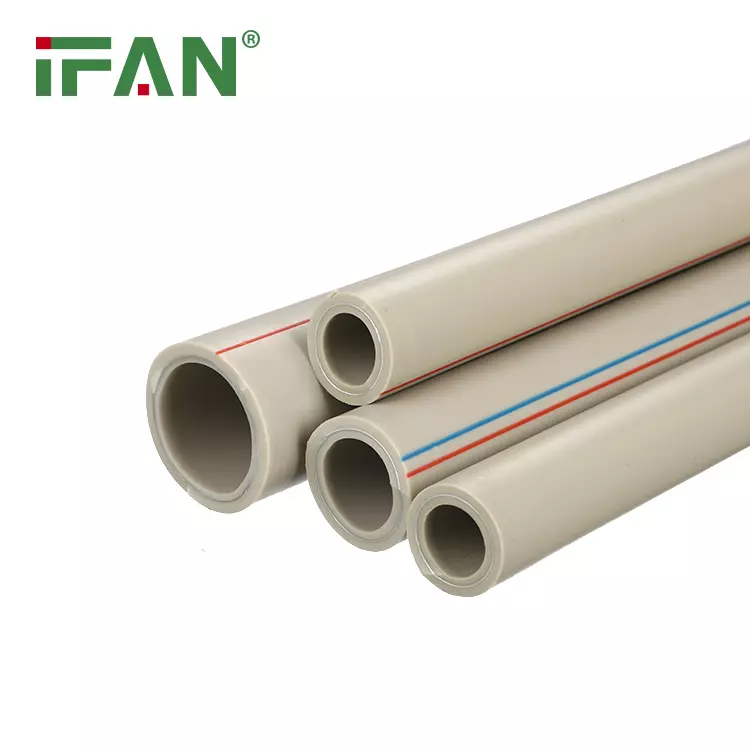

| Product Name |

IFAN Polypropylene Blue PPR Socket |

| Color |

Green,White,Grey,Yellow,Blue,Coffee Color Or Customized |

| Size |

20-125mm Or Customized |

| Material |

PPR |

| Package |

Opp Bag+Cartoon |

| Standard |

ISO 15874,EN 15874,ASTM F2389,DIN 8077/8078,GB/T 18742,NBR 15884 |

| OEM |

Aviable |

| Sample |

Free Provide |

| Contact US |

Whatsapp:+8613373827623 E-mail:[email protected] |

We have 30+ years of plumbing experience, a wide range of products, support customization and free samples. This IFAN Facebook:https://www.facebook.com/IFANPiping, welcome to contact us. If you are interested in IFAN’s PPR Pipe Fittings, please feel free to send us a message; we will send you the price list and product catalogue in time.

Material Properties of PPR

PPR, or polypropylene random copolymer, is known for its durability and resistance to high temperatures. PPR sockets can withstand temperatures up to 95°C (203°F). This high thermal resistance makes them suitable for hot water applications.

Additionally, PPR is resistant to corrosion and chemical damage. Unlike metal pipes, PPR does not rust or degrade when exposed to various chemicals. This property is vital in industrial settings, where fluids often contain aggressive substances. The longevity of PPR sockets reduces maintenance costs and downtime.

Advantages of PPR Sockets

One of the main advantages of PPR sockets is their lightweight nature. Compared to metal fittings, PPR sockets are much lighter. This makes transportation and installation easier, reducing labor costs. Workers can handle PPR sockets without heavy equipment.

PPR sockets also offer excellent thermal insulation. This insulation helps maintain the temperature of the fluids within the pipes. In applications involving hot water, this feature can improve energy efficiency. As a result, industries can reduce energy costs associated with heating.

Applications in Water Supply Systems

In industrial water supply systems, PPR sockets are commonly used. They connect pipes in various configurations, ensuring a reliable flow of water. For example, in a manufacturing plant, PPR sockets can connect main supply lines to distribution branches.

These sockets help ensure consistent water pressure throughout the facility. Proper water supply is crucial for various processes, including cooling and cleaning. The durability of PPR sockets ensures that these processes run smoothly without interruptions.

Use in Chemical Transport

PPR sockets are also suitable for chemical transport applications. Their resistance to corrosive substances allows them to handle a wide range of chemicals. Industries that require safe and efficient transport of chemicals often choose PPR sockets.

For instance, a chemical processing facility may use PPR sockets to connect pipes carrying acids or bases. The reliability of PPR fittings minimizes the risk of leaks or failures. This safety feature is critical in protecting workers and the environment.

Air Conditioning and Refrigeration

In air conditioning and refrigeration systems, PPR sockets play an important role. They are used to connect pipes that transport refrigerants and cooling fluids. The thermal insulation properties of PPR help maintain the efficiency of these systems.

For example, in a large commercial building, PPR sockets can be used in chilled water systems. These systems require precise temperature control to maintain comfort. PPR sockets contribute to the overall efficiency of the cooling system, reducing energy consumption.

Ease of Installation

The installation of PPR sockets is straightforward. Their lightweight design makes handling and positioning easy. Workers can quickly assemble piping systems, which speeds up project timelines. This efficiency is especially beneficial in large-scale industrial projects.

Moreover, PPR sockets can be joined using heat fusion techniques. This method creates strong, leak-proof connections. The simplicity of the installation process helps reduce the likelihood of errors during assembly.

Cost-Effectiveness

PPR sockets offer excellent cost-effectiveness for industrial applications. While their initial purchase price may be competitive, their longevity and low maintenance needs provide significant savings over time. Industries can reduce downtime associated with repairs and replacements.

For instance, a factory that switches to PPR sockets may see a decrease in maintenance costs. The durability of these fittings means fewer replacements are necessary, leading to lower overall expenditures. This financial advantage is attractive to many businesses.

Environmental Considerations

PPR is an environmentally friendly material. It is free from harmful chemicals, making it safe for various applications. Additionally, PPR sockets are recyclable, contributing to sustainability efforts. Industries that prioritize eco-friendly practices can benefit from using PPR products.

By implementing PPR sockets in their piping systems, companies can enhance their sustainability profile. Efficient water use and reduced waste are important for meeting environmental regulations. Using PPR fittings aligns with these goals.

Case Studies in Industrial Applications

Several industries have successfully integrated PPR sockets into their piping systems. In one case, a food processing plant improved efficiency by using PPR for water supply. The lightweight and corrosion-resistant properties led to fewer maintenance issues.

Another example involves a chemical manufacturer that switched to PPR sockets for safety reasons. The ability to transport corrosive substances without leaks enhanced overall workplace safety. These real-world examples highlight the practical benefits of PPR sockets in industrial settings.

IFAN International Standard for PPR Tubing

IFAN recognizes several important standards for PPR (polypropylene random copolymer) piping systems to ensure their quality and performance. These include ISO 15874 and EN 15874, which set international standards for PPR pipes and fittings; ASTM F2389, which specifies requirements for PPR pipes used in pressure applications; DIN 8077/8078, which provides specifications for PPR pipes and fittings in Germany; GB/T 18742, which covers PPR pipes in China; and NBR 15884, which outlines standards for PPR pipes and fittings in Brazil. These standards collectively ensure that PPR products meet rigorous global quality and performance criteria.

Conclusion

In conclusion, PPR sockets are vital components in industrial piping systems. Their material properties, ease of installation, and cost-effectiveness make them an excellent choice for various applications. From water supply to chemical transport, PPR sockets offer reliable solutions.

As industries continue to seek efficient and sustainable piping options, PPR sockets will remain a popular choice. By understanding their advantages, companies can make informed decisions that enhance their operations. Embracing PPR technology can lead to improved efficiency, safety, and sustainability in industrial settings.

FAQ

1.What products does IFAN produce?

IFAN integrates R&D, production, sales and service, and provides comprehensive plumbing system solutions. The company’s main product lines cover construction engineering, municipal pipelines, agricultural irrigation, home improvement, fire protection, industrial pipelines, gas pipelines, bathrooms and other systems, providing water supply, drainage, waterproofing, floor heating, bathing, hardware plumbing and other modules. The company provides a variety of products such as pipes, pipe fittings, valves, etc., covering PP-R, PVC-U, Ball Valve, Water Tap, PEX, CPVC, PP and other series.

2.Where is IFAN export factory located in?

No. 3, Central Road, Diankou Town, Zhuji City, Shaoxing City, Zhejiang Province

3.How is the package?

1. Our outer boxes are generally in the format of IFAN unified boxes, and OPP bags and cartons are uniformly packaged. 2. Our products usually use different packaging according to different product types. 3. In addition, we can also customize packaging according to different needs. Adopt customer opinions on product packaging, design packaging and customize Logo.

4.Why should I choose you among so many factories?

1. IFAN products have deeply covered many countries around the world, with rich product varieties, complete qualifications, and strong brand influence, helping you to expand the market faster. 2. We have a stable sales team and long-term experience, and can grasp customer needs in time. 3. Mutual benefit and win-win can lead to sustainable development. 4. Provide customers with perfect after-sales service

5. What is your product advantage?

1. From production to shipment, we have advanced production machines and a very strict management system. 2. Our products are designed, molded, and produced in accordance with international standards. Quality control mainly includes the inspection of the first piece, process, packaging, and finished products. Only qualified products are packaged. 3. We not only have our own laboratory for testing, but also send samples to authoritative certification agencies every year to ensure the long-term quality of products. 4. Our products have different connection methods, including glue, hot melt, electric fusion, thread, etc., which can meet different needs. 5. Our product prices are very competitive, and the company provides free samples to let customers see the quality of the products.

评价

目前还没有评价