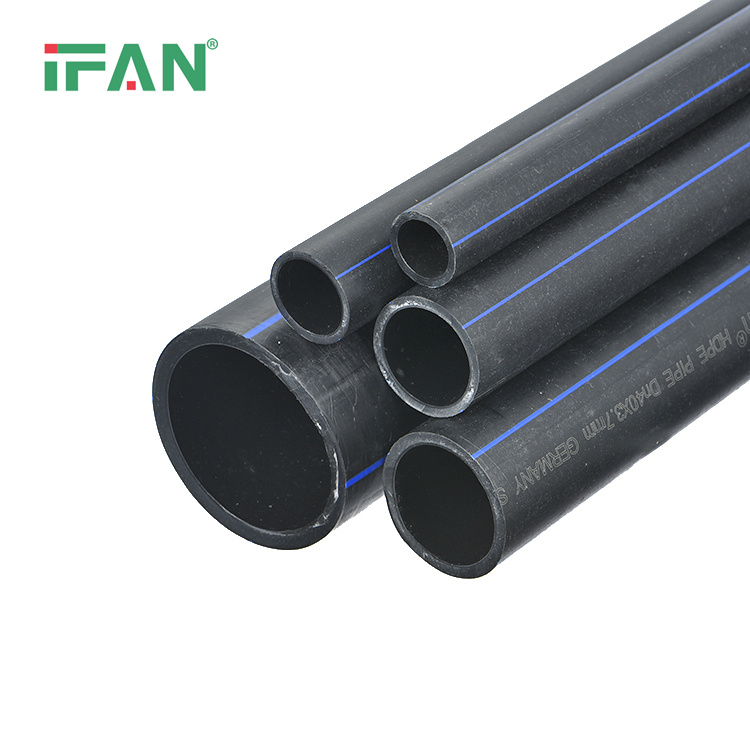

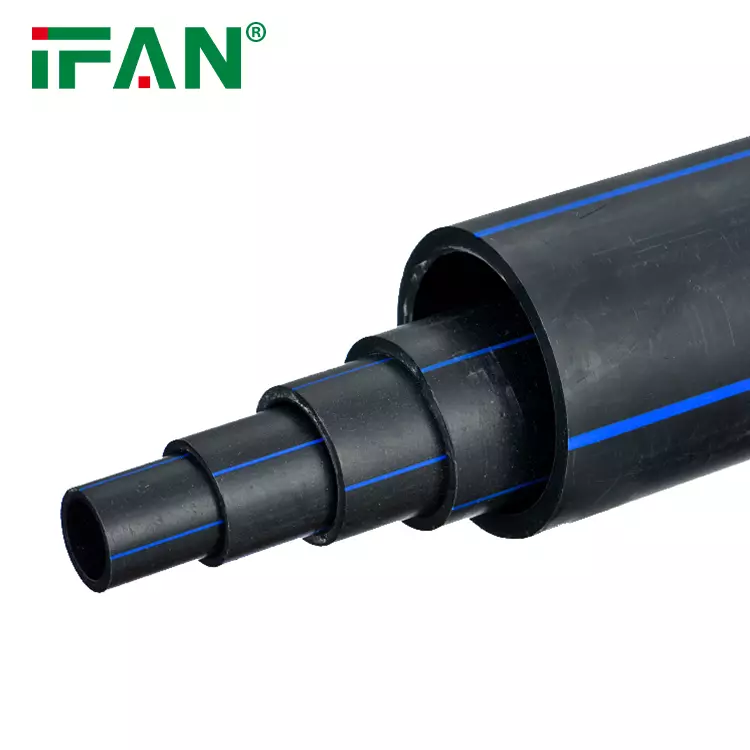

High-Density Polyethylene (HDPE) pipe fittings play a crucial role in modern piping systems. These fittings, known for their versatility and durability, are essential components in various industries. In this article, we will delve into the world of HDPE pipe fittings, exploring their types, applications, and advantages.

1.Understanding HDPE Pipe Fitting

HDPE pipe fittings are components that connect, control, or adapt HDPE pipes in a piping system. They withstand demanding applications and excel in resisting corrosion, chemicals, and wear. These fittings come in various forms, each serving specific purposes.

2.Types of HDPE Fittings

There is a wide range of HDPE fittings available to cater to diverse requirements.

HDPE Pipe Fitting: These fitting join two or more HDPE pipes, ensuring a secure, leak-free connection. Common types include couplers, reducers, and elbows.

Special Application HDPE Fittings: Certain applications require specialized fittings, such as HDPE flanges for connecting pipes to other equipment. These flanges offer exceptional sealing properties.

Irrigation Fittings: HDPE fittings are indispensable in irrigation systems. They include components like drip line connectors, sprinkler adapters, and irrigation control valves. Engineers design these fittings to meet the unique demands of agricultural and landscaping applications.

3.Applications of HDPE Pipe Fittings

HDPE pipe fitting find applications in a wide range of industries, including:

Water Supply: HDPE pipe fittings are extensively used in water supply systems due to their corrosion resistance and ability to safely transport potable water.

Sewer Systems: These fittings are employed in sewer systems, where their durability and leak-resistant properties are crucial for efficient, long-lasting infrastructure.

Irrigation Systems: In irrigation systems, HDPE fittings play a pivotal role. They facilitate the precise distribution of water to crops and landscapes, ensuring efficient water management.

Chemical Processing: HDPE fittings find application in chemical processing plants due to their resistance to a wide range of chemicals, making them suitable for conveying various substances.

4.Advantages of HDPE Pipe Fitting

HDPE pipe fittings offer several advantages:

Exceptional Durability: HDPE fittings have a long service life and can withstand harsh environmental conditions.

Chemical Resistance: They are resistant to a wide range of chemicals, making them suitable for various applications.

Leak-Free Joints: HDPE fittings ensure the integrity of the piping system with their leak-free joints.

Flexibility: HDPE fittings are flexible and can adapt to changing conditions, reducing the need for expansion joints.

Conclusion

In conclusion, IFAN HDPE pipe fitting are versatile, durable, and essential components in modern piping systems. Whether used in water supply, sewer systems, irrigation, or chemical processing, these fittings provide reliable performance. Understanding the types, applications, and advantages of HDPE pipe fittings is crucial for designing and maintaining efficient piping systems across various industries.