Ball valves, known for their adaptability and efficiency, are indispensable components in fluid control systems across various industries. In this article, we will explore the diverse applications, unique features, and proper maintenance practices associated with ball valves.

Design and Functionality

Understanding the design and functionality of ball valve is crucial for their effective use:

Spherical Closure: The hallmark of a ball valve is its spherical closure element, which pivots to control the flow of fluids. The hole, or bore, within the ball allows or restricts the passage of the fluid.

Actuation Methods: Ball valve can be operated using various methods, including manual handles, levers, or automatic actuators. This flexibility makes them suitable for a wide range of applications.

Seats and Seals: Ball valve employ seats and seals, often made from materials like PTFE, to create a reliable seal when the valve is closed, ensuring zero leakage.

Applications

Ball valve find versatile applications in different industries:

Oil and Gas: In the oil and gas sector, ball valve are used for on-off control of the flow of crude oil, natural gas, and other petrochemical products.

Chemical Industry: Ball valve are the preferred choice for handling corrosive chemicals, thanks to their resistance to corrosion and chemical compatibility.

Water Treatment: Brass ball valve are instrumental in the water treatment industry, facilitating the control of various water treatment processes, including filtering, chlorination, and pH adjustment.

Unique Features of Ball Valve

Ball valves offer several unique features:

Quick Operation: They provide rapid open-close functionality, which is crucial in emergency shut-off situations.

Minimal Maintenance: Ball valve typically require minimal maintenance, reducing operational downtime.

Bi-Directional Flow: Ball valves can handle fluid flow in both directions, making them adaptable to a wide range of applications.

Maintenance Practices

Proper maintenance ensures the longevity of ball valve:

Regular Lubrication: Periodic lubrication of the valve’s seats and seals helps maintain their effectiveness.

Leak Detection: Conduct regular leak checks to identify and address any potential issues promptly.

Actuator Inspection: For automated ball valves, inspect actuators for proper functioning and connectivity.

Conclusion

Ball valves, with their versatile applications, design flexibility, and minimal maintenance requirements, play a crucial role in fluid control systems across various industries. Understanding their design, applications, unique features, and proper maintenance practices is essential for ensuring efficient and reliable fluid flow control. As industries continue to rely on precise fluid management, ball valves remain at the forefront of this critical technology.

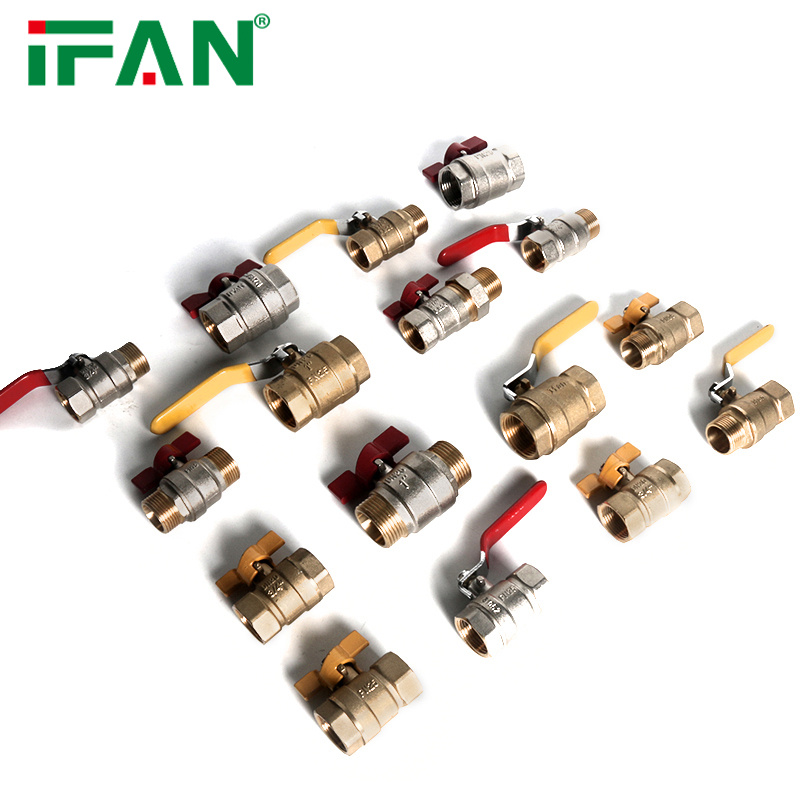

IFAN has 30+ years of plumbing experience. We have a wide range of Brass Ball Valve, sizes and colors. Welcome to contact us.