PPH (polypropylene homopolymer) and PPR (polypropylene random copolymer) pipes are widely used in various applications. This article aims to explore the dissimilarities between these two types of pipe, along with a brief overview of PPH fittings.

PPH Pipes:

PPH pipes consist of pure polypropylene, offering exceptional resistance to chemicals and stability at high temperatures. These pipes find extensive use in industries involving corrosive substances, such as chemical processing, pharmaceuticals, and food production. Moreover, PPH pipes possess excellent insulation properties, making them suitable for hot water supply and heating systems in buildings. However, it is important to note that PPH pipe are not recommended for applications involving high pressure or impact loads due to their susceptibility to cracking and deformation.

PPR Pipes:

PPR pipes differ from PPH pipe as they contain a small amount of ethylene propylene rubber (EPDM) or other elastomers. This addition enhances their flexibility and impact resistance, making them ideal for plumbing systems in residential and commercial buildings. The smooth interior surface of PPR pipes prevents clogging and scaling, ensuring efficient water transportation. Additionally, PPR pipes can withstand high pressures and temperatures of up to 90°C. They offer easy installation, low maintenance, and a long service life of approximately 50 years.

PPH Fittings:

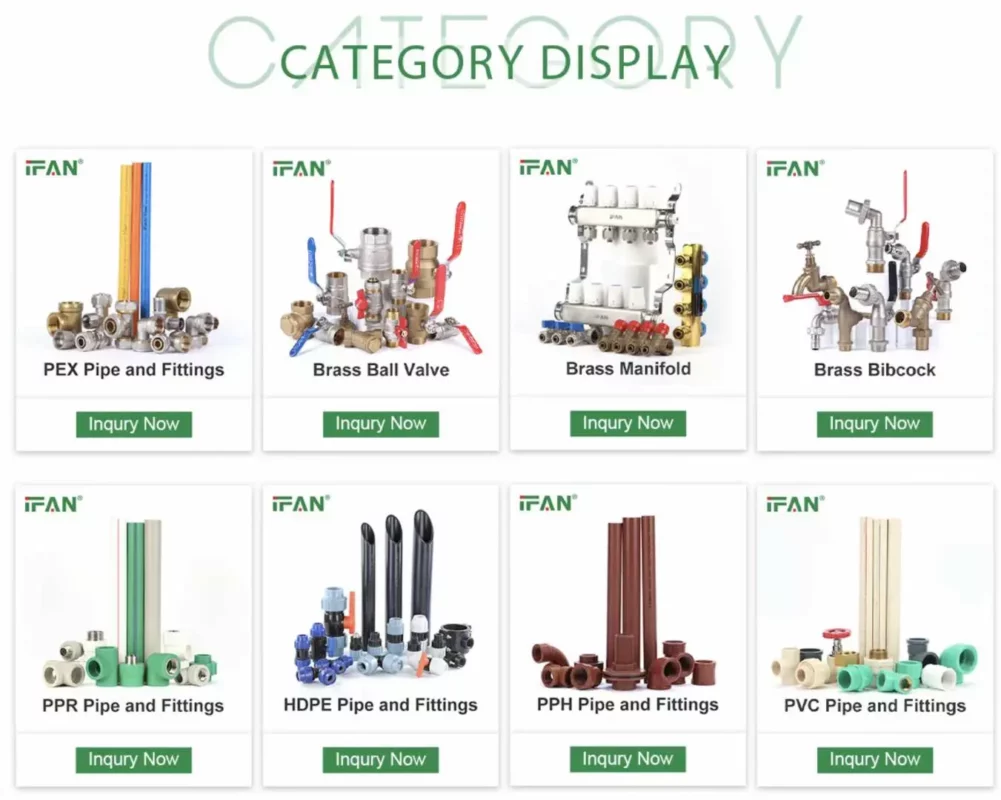

PPH fittings play a vital role in connecting PPH pipe and controlling fluid flow within the piping system. These fittings come in various shapes and sizes, including elbows, tees, reducers, couplings, and flanges. When joining PPH pipe, it is crucial to select compatible fittings and employ appropriate installation techniques. Welding or fusing PPH fittings to the pipes using methods like hot air or electrofusion ensures a secure connection. To maintain system integrity, it is essential to choose PPH fittings that exhibit the same chemical resistance and temperature tolerance as the pipes. This ensures leak-free performance without any blockages.

Conclusion:

In conclusion, understanding the disparities between PPH and PPR pipes is crucial for selecting the appropriate piping solution for each application. PPH pipes excel in industries where chemical resistance and high-temperature stability are paramount. On the other hand, PPR pipes are favored in plumbing systems due to their flexibility, impact resistance, and ease of installation. Both types of pipes have their specific applications, and choosing the right type is vital for ensuring a reliable and efficient system. By incorporating compatible PPH fittings, one can further enhance the overall performance and longevity of the piping system.

If you have read this article and have any questions, please feel free to contact IFAN. Below is our contact information:

Whatsapp:+86 13373827623

Email:[email protected]