UPVC threaded fittings are mainly connected in the following ways:

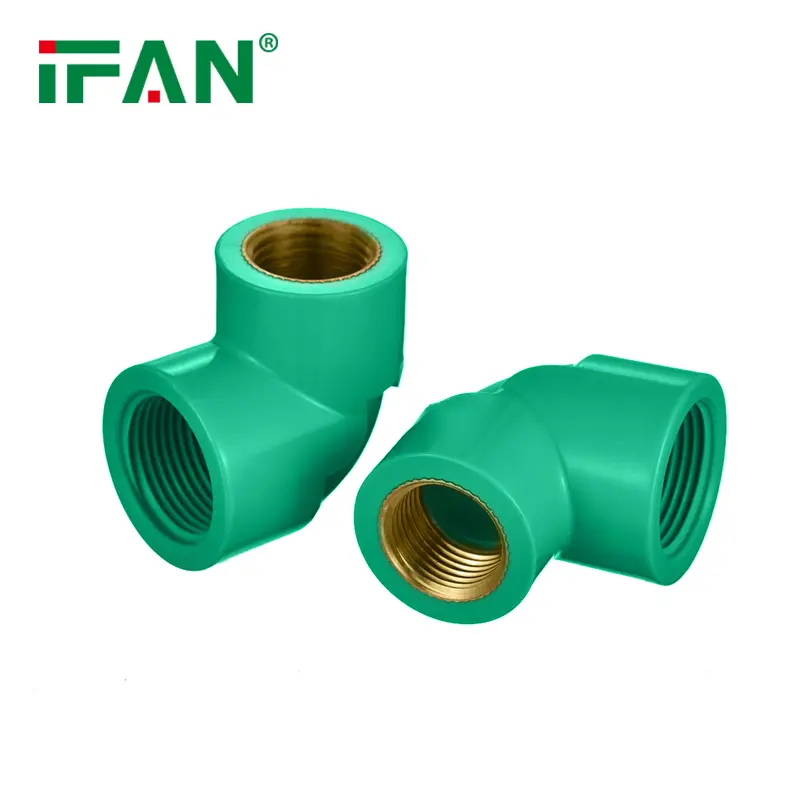

Threaded connection:

- Advantages: This is a simple and detachable connection. It is suitable for scenarios that require frequent disassembly and replacement, such as maintenance and renovation projects. It connects the two pipes by cutting threads on the pipe interface and using the corresponding connector. It has good sealing performance.

- Disadvantages: Although the threaded connection has good sealing performance, it may not be stable enough for scenarios under high pressure.

Socket connection:

- Advantages: This is a convenient and fast connection method, especially suitable for UPVC piping systems with small diameters. Such as household drainage system. It is done by installing the corresponding socket on the pipe interface. The pipe is fixed to the joint using a specific fixing method, and the connection process is relatively simple.

- Disadvantages: For scenarios under high pressure, the socket connection may not be strong enough.

Flange connection:

- Advantages: Flange connection is a high-strength connection. It is suitable for applications that require high pressure and vibration, such as industrial piping systems. It works by installing flanges on the pipe interface and using bolts to hold the two flanges together. It has good sealing performance and reliability.

- Disadvantages: The installation and maintenance of flange connections is relatively complex and requires a high level of technology.

When selecting the connection mode, it is necessary to consider the specific project requirements, pipeline specifications, and use environment. For example, if the plumbing system requires frequent disassembly and maintenance, then threaded connections may be a better option. If the piping system needs to withstand greater pressure and vibration, then the flange connection may be more suitable. At the same time, it is also necessary to pay attention to the sealing performance and installation technical requirements of various connection methods. To ensure the safe, stable and efficient operation of the pipeline system.

Contact

If you have read this article and have any questions, please feel free to contact IFAN. Below is our contact information:

Whatsapp:+86 13373827623

Email:[email protected]