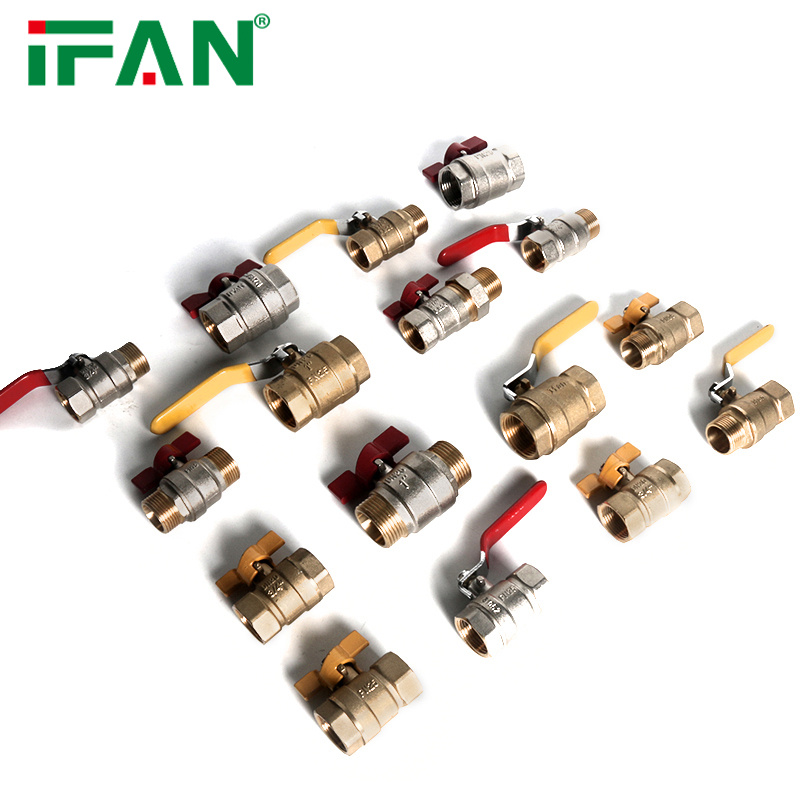

Brass mini ball valves are renowned for their compact design, which makes them highly suitable for various applications where space is at a premium. This compactness does not compromise their performance; rather, it enhances their versatility and ease of integration into tight spaces.

Definition and Importance

A brass mini ball valve is a small, durable valve used to control fluid flow through pipes. The term “mini” indicates that the valve is smaller than standard-sized ball valves. Its compact design is crucial for applications where space constraints exist. Despite their size, these valves offer reliable performance and robust construction.

Design Features

The compact design of a brass mini ball valve includes several key features:

1. Reduced Dimensions: These valves are smaller in diameter and length compared to standard ball valves. This allows them to fit into tight spaces where larger valves cannot be accommodated.

2. Precision Engineering: The internal components are precisely engineered to ensure that the valve operates smoothly despite its small size. This includes the ball, seat, and stem, which are all manufactured to tight tolerances.

3. Streamlined Shape: The valve body is designed to minimize any excess bulk. This streamlined shape helps in reducing the space needed for installation.

Material and Durability

Brass is chosen for its strength and durability. The use of brass in mini ball valves ensures that the valve can withstand high pressures and temperatures despite its compact size. Brass also provides excellent resistance to corrosion, which is essential for maintaining valve functionality over time.

Applications

The compact design of brass mini ball valves makes them ideal for a wide range of applications:

1. Residential Plumbing: In residential settings, these valves are used under sinks, in tight cabinet spaces, or behind appliances. Their small size allows easy installation and operation in areas with limited space.

2. Industrial Equipment: Many industrial machines and systems use brass mini ball valves to control fluids in cramped machinery spaces. Their compact size helps in managing flow in compact or densely packed systems.

3. Automotive: In automotive applications, these valves are used in fuel and coolant systems where space is constrained. Their small size is perfect for fitting within the engine compartment or other compact areas.

4. HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, these valves help regulate flow in confined spaces. Their compact design allows for easier integration into complex HVAC setups.

Installation and Maintenance

The ease of installation and maintenance is enhanced by the compact design of brass mini ball valves:

1. Installation: The small size allows for straightforward installation in tight spaces. The valve can be easily fitted into existing piping systems without requiring major modifications.

2. Accessibility: In systems where space is limited, being able to access and operate the valve efficiently is crucial. The compact design ensures that the valve remains accessible for operation and maintenance.

Example

Consider a residential water filtration system where space under the sink is limited. A standard-sized valve might be too large to fit comfortably. In this scenario, a brass mini ball valve is used to control the water flow to the filter. Its small size allows it to be installed without crowding other components or impeding access.

Advantages

The compact design of brass mini ball valves offers several advantages:

1. Space Efficiency: By fitting into smaller spaces, these valves help optimize the use of available space. This is particularly beneficial in environments where every inch counts.

2. Versatility: Their small size allows them to be used in a variety of applications, from residential to industrial settings. This versatility makes them a popular choice for many different systems.

3. Ease of Operation: Despite their size, mini ball valves are designed for easy operation. The lever or handle is usually positioned for convenient access, allowing for smooth and efficient flow control.

Challenges

While the compact design offers many benefits, there are some challenges to consider:

1. Flow Capacity: The smaller size of the valve may limit the flow capacity compared to larger valves. This needs to be considered when designing systems that require high flow rates.

2. Complexity: Manufacturing mini ball valves requires precise engineering and high-quality materials. The complexity of making a small, reliable valve can drive up costs.

Conclusion

The compact design of brass mini ball valves provides a practical solution for controlling fluid flow in spaces where size is a constraint. Their reduced dimensions, combined with the durability and precision of brass, make them suitable for a variety of applications. Whether in residential plumbing, industrial machinery, automotive systems, or HVAC setups, these valves offer a reliable and efficient way to manage fluid flow while optimizing space usage.

If you have read this article and have any questions, please feel free to contact IFAN. Below is our contact information:

Whatsapp:+86 13373827623

Email:[email protected]