Introduction

PPR welding machines join PPR pipes securely. These machines use heat to melt pipe ends and fittings, creating a solid bond. Proper use and maintenance ensure long-lasting, leak-proof connections. Follow these tips to maximize the efficiency and effectiveness of your PPR welding machine.

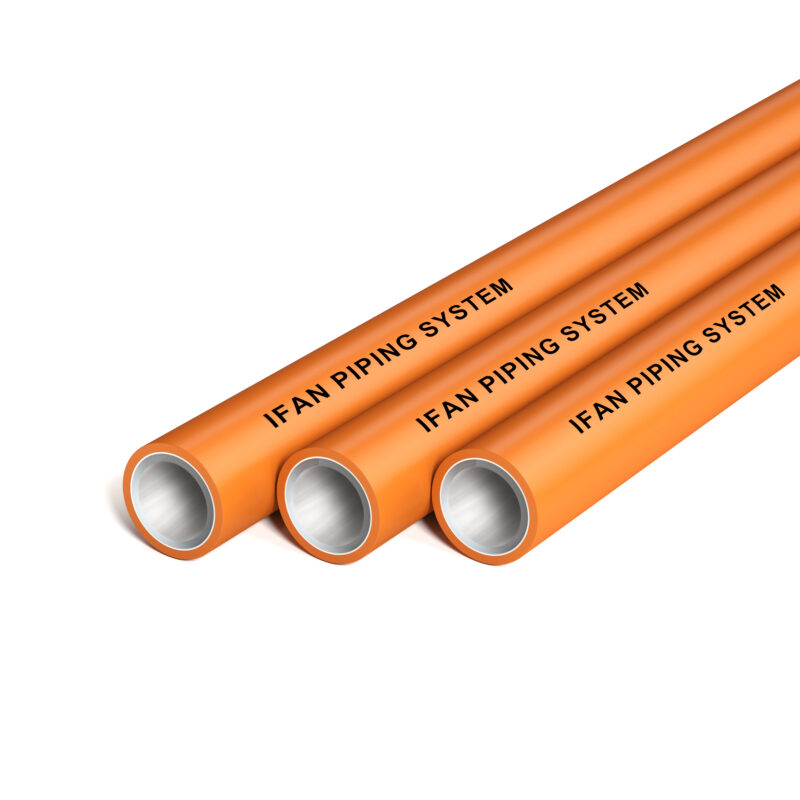

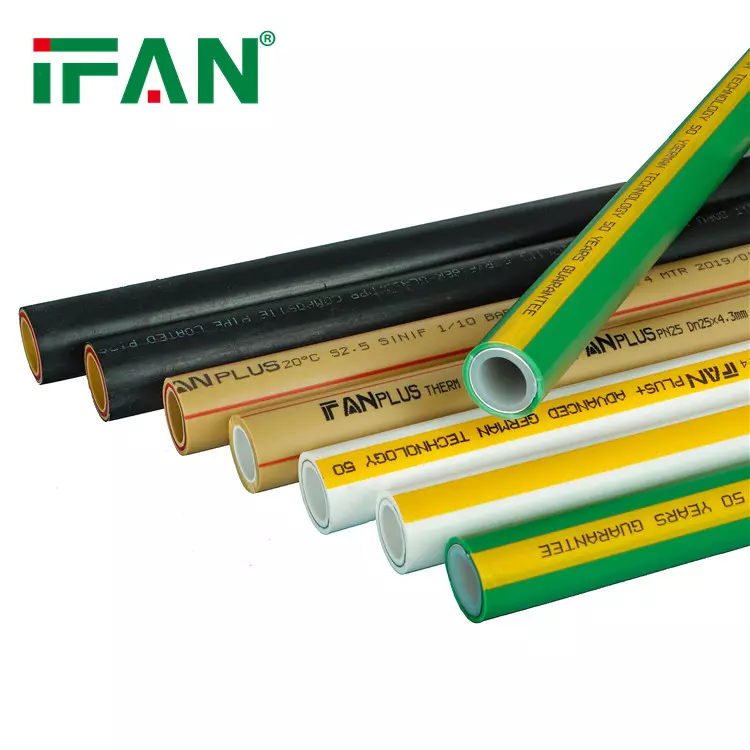

Product Information

We have 30+ years of plumbing experience, a wide range of products, support customization and free samples. This IFAN Facebook:https://www.facebook.com/IFANPiping, welcome to contact us.

If you are interested in IFAN’s PPR Welding Machine, please feel free to send us a message; we will send you the price list and product catalogue in time.

Tips for PPR Welding Machine

Understanding the Basics

Know the basics of how a PPR welding machine works. It heats the pipe ends and fittings to a specified temperature. Once melted, you join the components, creating a seamless connection. Understanding this process helps you operate the machine correctly.

Selecting the Right Temperature

Adjust the welding machine to the correct temperature. For PPR pipes, the typical range is 260-280°C (500-536°F). Using the right temperature prevents overheating or underheating, which could weaken the joint.

Preparing the Pipes and Fittings

Clean the pipe ends and fittings before welding. Remove any dirt, dust, or oil to ensure a clean weld. Use a pipe cutter for straight, clean cuts. Proper preparation is essential for a strong, reliable connection.

Choosing the Correct Nozzles

Select the appropriate nozzle size for your pipes. Most machines come with different nozzle options. Ensure the nozzle fits the pipe diameter to ensure even heating and proper alignment.

Heating the Pipes Properly

Place the pipes and fittings in the heating element. Allow them to heat for the recommended time. Avoid moving the components during this period to ensure uniform heating. Proper heating is crucial for a strong weld.

Aligning the Pipes and Fittings

After heating, quickly align the pipes and fittings. Push them together firmly and ensure they are straight. Hold them in place briefly to allow the material to cool and solidify.

Cooling the Weld Joint

Let the welded pipes cool naturally. Do not apply any pressure or force during the cooling process. Proper cooling helps achieve a strong, leak-proof weld and prevents joint failure.

Inspecting the Weld Quality

Examine the weld joint after cooling. Check for smoothness and consistency. Look for any gaps or defects that could indicate a poor weld. A successful weld should be even and free of visible issues.

Maintaining the Welding Machine

Regularly clean and maintain your welding machine. Check for signs of wear or damage. Replace any worn parts promptly to maintain optimal performance and extend the machine’s lifespan.

Safety Precautions

Always prioritize safety when using a PPR welding machine. Wear protective gear, including gloves and safety glasses. Ensure proper ventilation in your workspace to avoid inhaling fumes from the heating process.

Troubleshooting Common Problems

Address common issues such as weak joints or leaks by checking the machine’s temperature and heating time. Ensure the pipes and fittings are clean and properly aligned. Refer to the machine’s manual for specific troubleshooting advice.

Using the Machine Efficiently

Use the machine efficiently by following the manufacturer’s guidelines. Familiarize yourself with the controls and settings. Efficient operation reduces errors and improves the quality of your welds.

Evaluating Machine Performance

Regularly assess the performance of your welding machine. Pay attention to any changes in efficiency or quality. Regular evaluation helps ensure the machine continues to perform well.

Seeking Professional Help

If you encounter persistent issues, consider consulting a professional. A technician can provide expert advice and repair services. Professional help ensures your machine operates at its best.

FAQ

1.What products does IFAN produce?

IFAN integrates R&D, production, sales and service, and provides comprehensive plumbing system solutions. The company’s main product lines cover construction engineering, municipal pipelines, agricultural irrigation, home improvement, fire protection, industrial pipelines, gas pipelines, bathrooms and other systems, providing water supply, drainage, waterproofing, floor heating, bathing, hardware plumbing and other modules. The company provides a variety of products such as pipes, pipe fittings, valves, etc., covering PP-R, PVC-U, Ball Valve, Water Tap, PEX, CPVC, PP and other series.

2.Where is IFAN export factory located in?

No. 3, Central Road, Diankou Town, Zhuji City, Shaoxing City, Zhejiang Province

3.How is the package?

1. Our outer boxes are generally in the format of IFAN unified boxes, and OPP bags and cartons are uniformly packaged.

2. Our products usually use different packaging according to different product types.

3. In addition, we can also customize packaging according to different needs. Adopt customer opinions on product packaging, design packaging and customize Logo.

4.Why should I choose you among so many factories?

1. IFAN products have deeply covered many countries around the world, with rich product varieties, complete qualifications, and strong brand influence, helping you to expand the market faster.

2. We have a stable sales team and long-term experience, and can grasp customer needs in time.

3. Mutual benefit and win-win can lead to sustainable development.

4. Provide customers with perfect after-sales service

5. What is your product advantage?

1. From production to shipment, we have advanced production machines and a very strict management system.

2. Our products are designed, molded, and produced in accordance with international standards. Quality control mainly includes the inspection of the first piece, process, packaging, and finished products. Only qualified products are packaged.

3. We not only have our own laboratory for testing, but also send samples to authoritative certification agencies every year to ensure the long-term quality of products.

4. Our products have different connection methods, including glue, hot melt, electric fusion, thread, etc., which can meet different needs.

5. Our product prices are very competitive, and the company provides free samples to let customers see the quality of the products.

评价

目前还没有评价